The introduction of the Next Gen NASCAR car has brought major changes to how teams approach race preparation and strategy, according to Phil Surgen, crew chief for Ross Chastain’s No. 1 Trackhouse Racing Chevrolet. Now in its fourth season, the Next Gen car continues to challenge teams with its design and setup, affecting how crews manage and optimize performance during races.

With several generations of NASCAR Cup cars behind them, from Generation 1 starting in 1948 to the latest Gen 7 model introduced in 2022, teams have continually adapted to evolving car specifications. The Next Gen car was designed to be a spec model with a more sports car-like structure, intended as a “plug-and-play” solution to simplify competition. However, in reality, it demands a high level of precision and labor-intensive work to reach top performance.

Challenges Presented by Precision and Complexity in the Next Gen Car

Phil Surgen detailed the difficulties in adjusting to the new car, emphasizing how small details now have a magnified impact.

“I wouldn’t agree with plug-and-play, but you can take all the parts,”

he said, highlighting that while the components are standardized, finely tuning the vehicle requires significant time and effort.

“There’s a lot of intricacies with these cars.”

Where past generations involved measurements in eighths or quarters of an inch, today’s tolerances are measured in thousandths of an inch.

“Years ago, we were dealing in eighths and quarters of an inch (tolerances), and now we’re dealing in 5-thou and 10-thou. The increments that we’re talking about have just — the scales have changed in magnitude of what used to matter to what matters now,”

Surgen explained. This extreme precision elevates the complexity of every step in car setup and inspection.

Importance of Equipment and Meticulous Setup in Achieving Competitiveness

Such minute tolerances mean that using the correct equipment properly becomes a crucial factor in avoiding inspection failures. Surgen pointed out the drastic upgrade in measurement technology.

“The complexity of the equipment we use just to measure the cars is significantly different than what it was before, and all the parts are available,”

he said, noting the advantage and responsibility that comes with having access to interchangeable parts.

Unlike previous generations, where building or repairing a car body took significant time, Next Gen bodies can be assembled rapidly using pre-made components.

“Before, building a body was not possible overnight. But you could put a Next Gen body together overnight because you could just take the parts off the shelf,”

Surgen added. Still, the challenge lies in assembling and configuring those parts to exacting standards required for racing success.

Delivering performance that can place the team among the front runners in a NASCAR Cup race demands detailed, precise configuration.

“Configuring them correctly at the level of detail that it takes to run in the front ten at a Cup race is a Herculean effort,”

Surgen said, underscoring the intense demands placed on the crew chiefs and their teams.

Implications for Future Races and Team Strategies

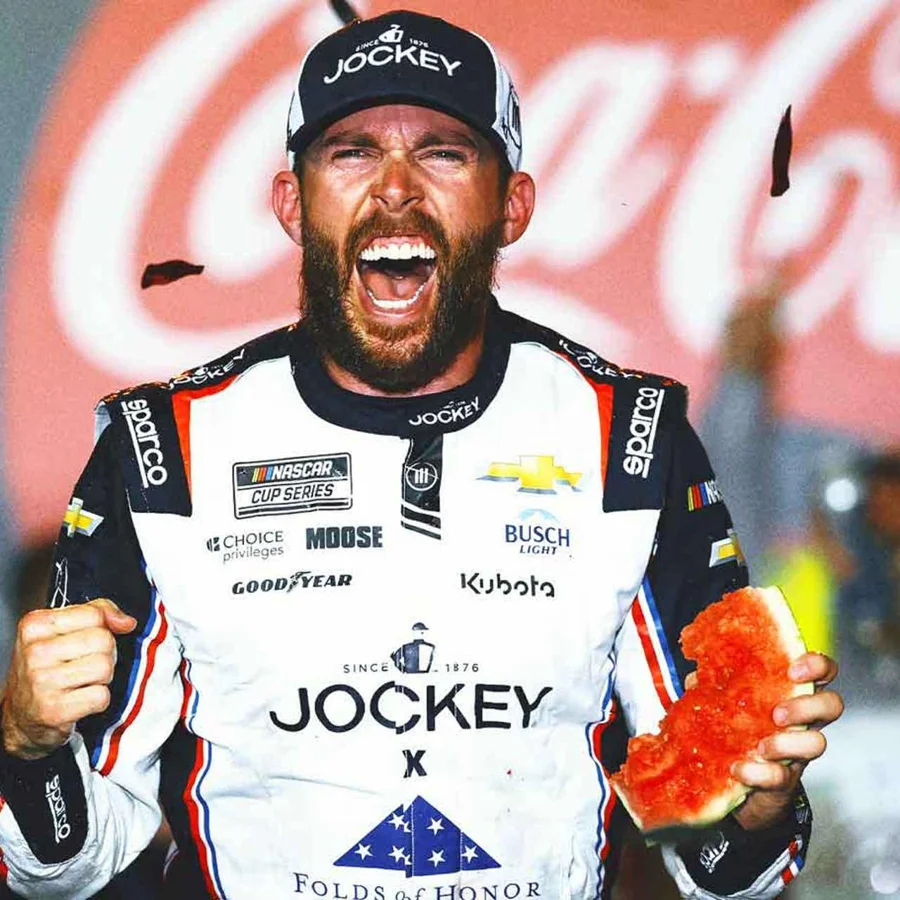

As the Next Gen car continues to test teams across the NASCAR circuit, crew chiefs like Phil Surgen are central to navigating these technical complexities. Ross Chastain’s recent victory at the Coca-Cola 600 and subsequent entry into the NASCAR playoffs illustrate how mastering these challenges can deliver competitive advantages. Going forward, teams will likely invest even more in precise measurements, equipment, and labor to fully exploit the Next Gen car’s design.

The evolving nature of the Next Gen car represents a dramatic shift within NASCAR, where standardized parts must be matched with exacting craftsmanship and strategy to succeed. The persistent fine-tuning and attention to detail required to meet inspection standards and race demands reflect a new era where teamwork and technical skill merge to push performance limits, redefining how races are won.